Bussiness Discription

Useful DMC products for life

Our group provides safety, affluence, and comfort in our customers' lives by creating products together with our customers. We will continue to create various solutions for the world by giving shape to the unlimited possibilities of Touchscreens.

-

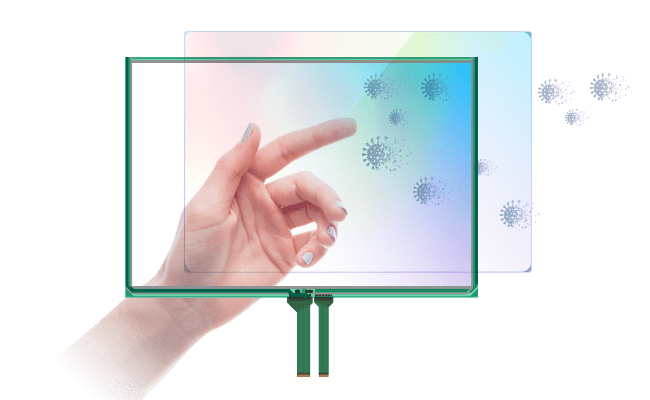

Medical EquipmentTouchscreens used in medical diagnostic, analytical, and testing equipment utilize smudge-proof and antibacterial films to prevent fingerprint smudges from obscuring the panel.

Medical EquipmentTouchscreens used in medical diagnostic, analytical, and testing equipment utilize smudge-proof and antibacterial films to prevent fingerprint smudges from obscuring the panel. -

Industrial EquipmentOur group has long been involved in the production of Touchscreens for industrial equipment, and we have a proven track record and have earned a high level of trust. We meet diverse needs such as long-term stable supply, long life, and cost containment.

Industrial EquipmentOur group has long been involved in the production of Touchscreens for industrial equipment, and we have a proven track record and have earned a high level of trust. We meet diverse needs such as long-term stable supply, long life, and cost containment. -

Vending MachineSince advertisements and other items are displayed on the panel screen while it is not in use, design is important. Products with high transparency and cover glass with printed designs are used to create a sense of quality.

Vending MachineSince advertisements and other items are displayed on the panel screen while it is not in use, design is important. Products with high transparency and cover glass with printed designs are used to create a sense of quality. -

Charging StationCharging stations are equipped with Touchscreens with guidance for easy operation by the user. For outdoor and semi-outdoor locations, projected capacitive systems may be used, which are resistant to UV rays and other weather conditions.

Charging StationCharging stations are equipped with Touchscreens with guidance for easy operation by the user. For outdoor and semi-outdoor locations, projected capacitive systems may be used, which are resistant to UV rays and other weather conditions. -

KIOSKKIOSKs are used by a wide range of people, from foreign residents and the elderly to children, so the intuitive Touchscreen is a good match for the application and is in increasing demand from society.

KIOSKKIOSKs are used by a wide range of people, from foreign residents and the elderly to children, so the intuitive Touchscreen is a good match for the application and is in increasing demand from society. -

Digital SignagePanels for reception, advertising, and information retrieval terminals that are used by an unspecified number of people are sometimes installed outdoors and are designed to be highly robust. In addition, Touchscreens are increasingly being used for large signage panels that exceed 40 inches in size.

Digital SignagePanels for reception, advertising, and information retrieval terminals that are used by an unspecified number of people are sometimes installed outdoors and are designed to be highly robust. In addition, Touchscreens are increasingly being used for large signage panels that exceed 40 inches in size.

Products and Services

In addition to more than 200 types of standard Touchscreen products, DMC has worked on more than 2,000 models of custom products. In order to meet the demands of our customers, we strive to develop products suitable for the environment and conditions in which they will be used, through close communication from the planning stage. In this way, through the manufacture, sale, and support of Touchscreens, we aim to engage with many people and grow together with them.

-

![]()

-

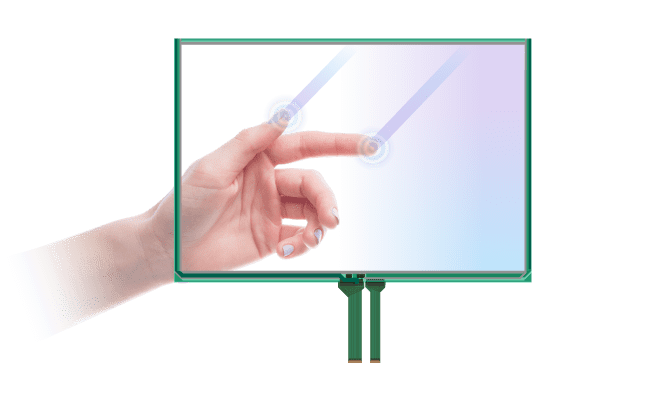

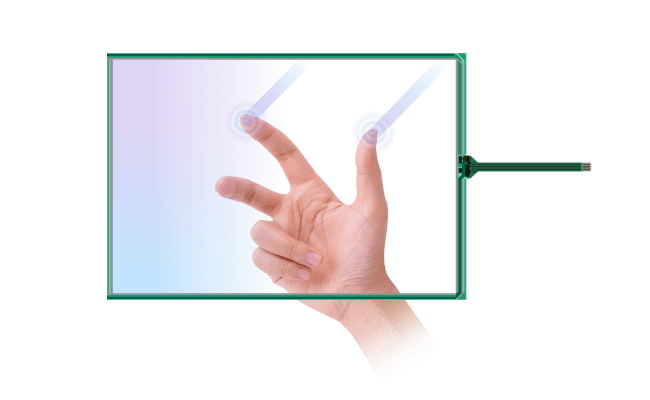

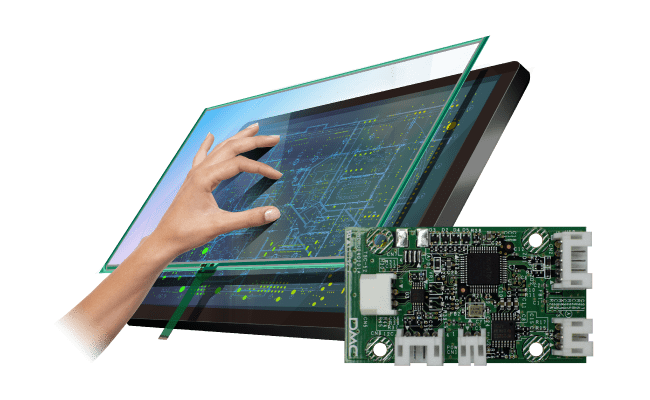

TOUCHSCREEN PRODUCTSResistive Touchscreen Products

It detects the position of a panel pressed by a finger, pen, etc. by measuring the voltage change. The system can be operated with gloves or other gloves, regardless of the input medium, and offers superior ease of use and reliable operability. The light-load type, which requires much less input load than the conventional resistive type, enables gesture operation like that of a smartphone. The multi-touch type offers a wider range of operations, while the single-touch type allows only a single point to be pressed.

VIEW MORE

-

![]()

Teaching Pendants

-

![]()

Industrial Equipment

-

![]()

Surveying & measuring instruments

-

![]()

Service Station POS

-

![]()

-

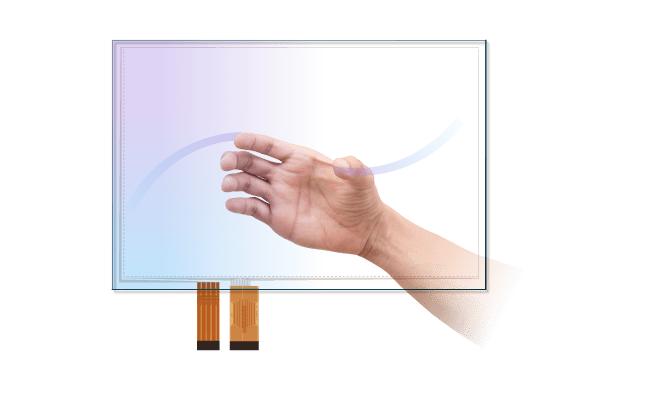

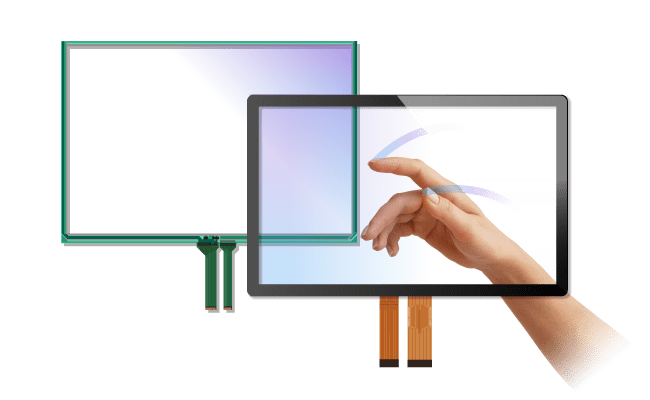

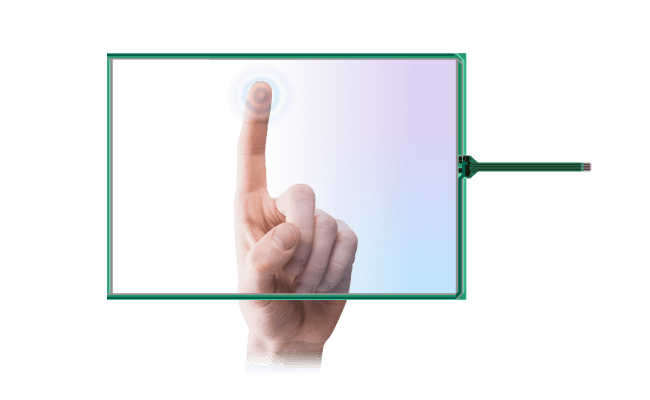

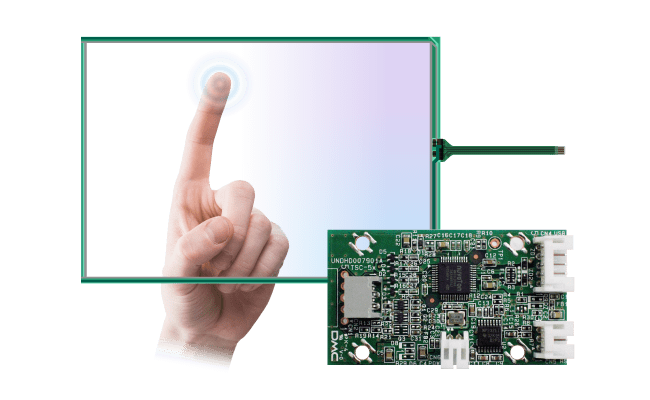

TOUCHSCREEN PRODUCTSCapacitive Touchscreen Products

Position is detected using electrical capacitive coupling that occurs when a finger touches the panel. We offer both a lightweight film/film construction type used in consumer products and a glass/glass construction type for industrial applications with excellent robustness and weather resistance.

VIEW MORE

-

![]()

Self-pay terminals in hospitals

-

![]()

Medical Equipment

-

![]()

Amusement Machine

-

![]()

POS Cash Register

-

![]()

-

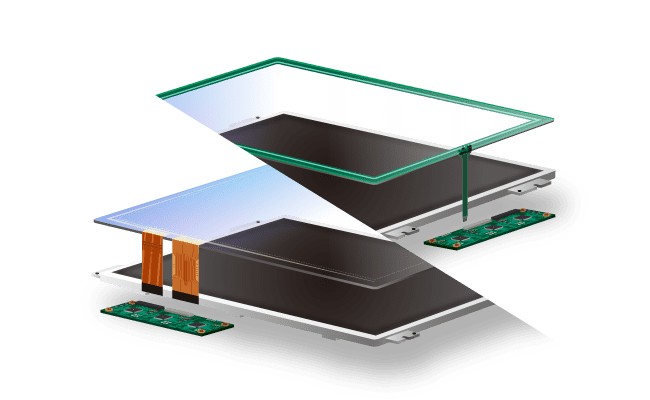

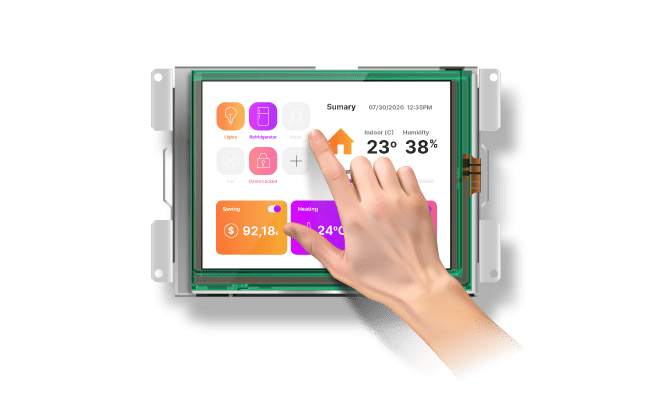

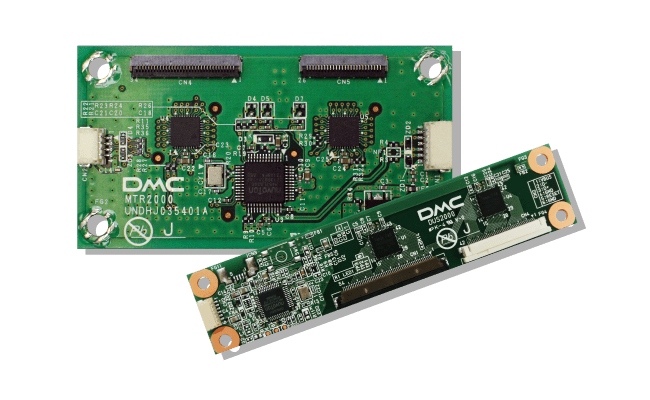

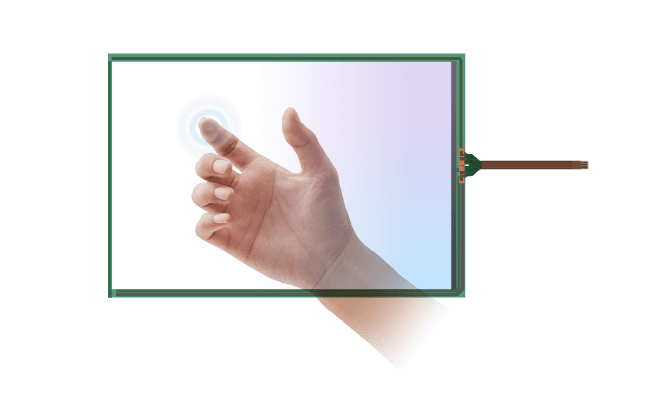

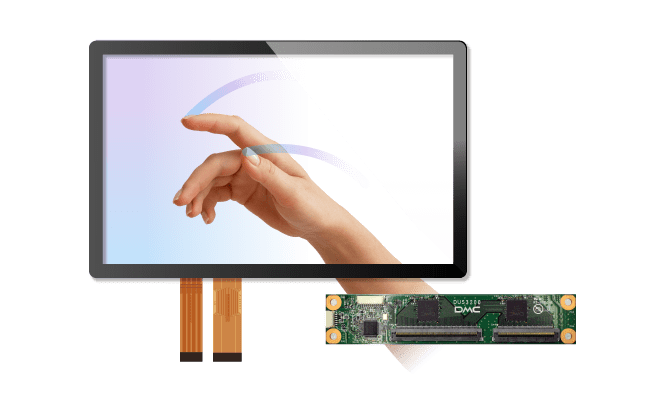

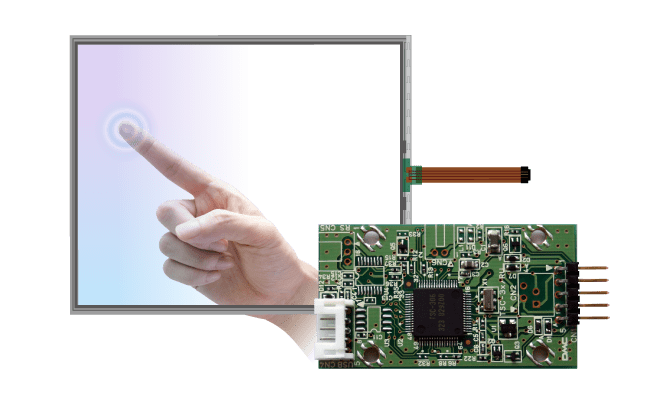

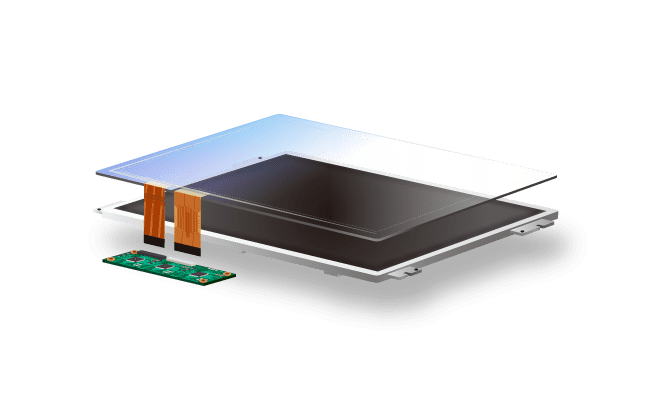

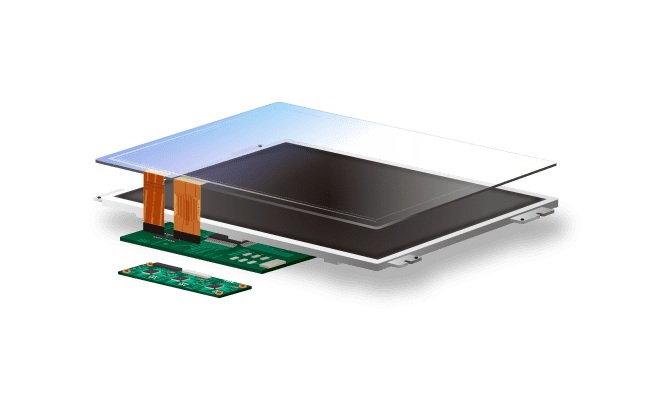

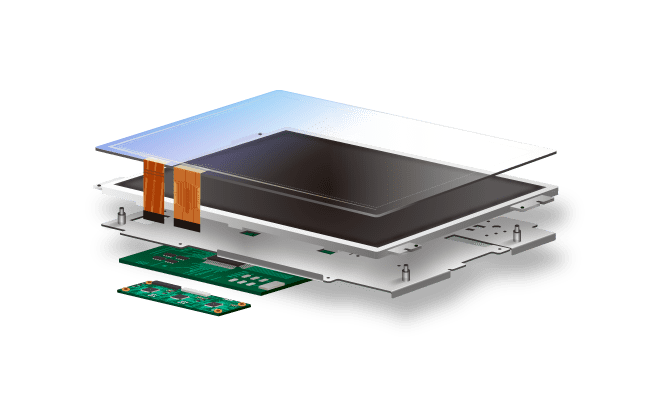

TOUCHSCREEN PRODUCTSTouchscreen Module Products

We develop, design, and manufacture Touchscreen module products that combine Touchscreen sensors, LCDs (liquid crystal displays), and Touchscreen controllers. Various customizable options provide appealing services with emphasis on design, and commonization of applications contributes to economic efficiency.

VIEW MORE

-

![]()

Semiconductor

-

![]()

Machine tool

-

![]()

Gas Station POS

-

![]()

Drink Servers

-

![]()

-

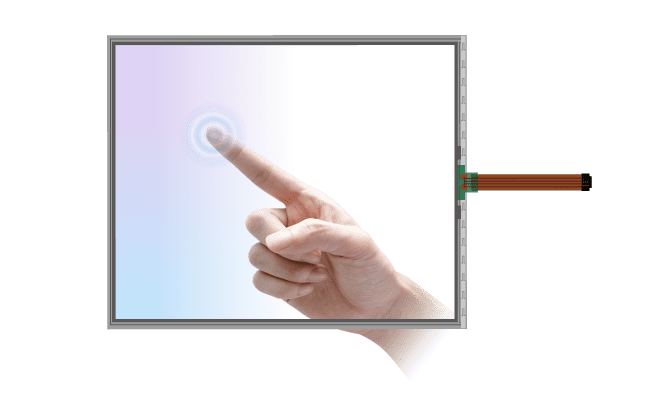

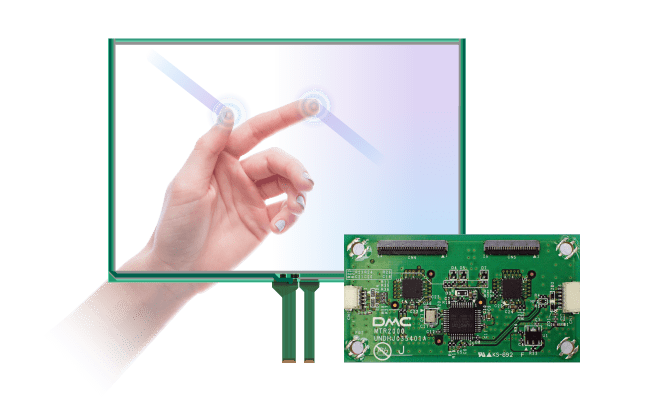

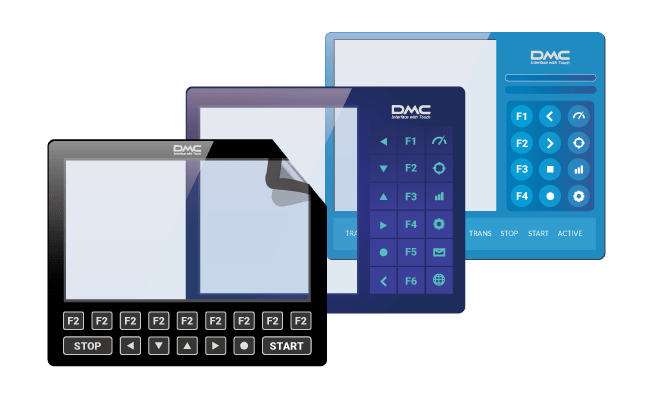

TOUCHSCREEN PRODUCTSTouchscreen Applied Products

We develop, design, and manufacture unit products indispensable for industrial equipment such as touch monitors, Touchscreen displays, and embedded panel controllers, etc. We also propose applications compatible with Linux OS and devices using advanced technologies.

-

![]()

Digital Signage

-

![]()

Teaching Pendants

-

![]()

Vending Machine

-

![]()

Ticket Machine

-

![]()

-

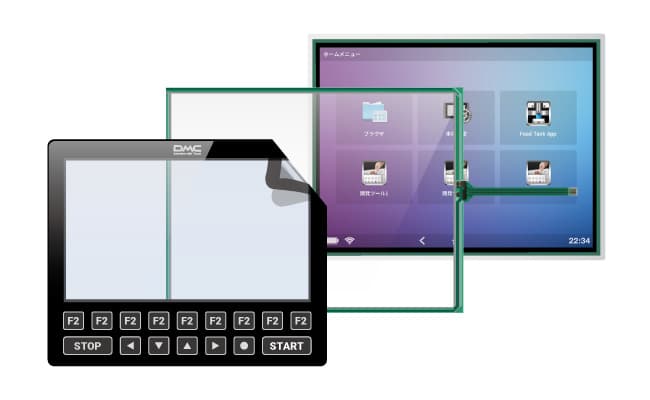

TOUCHSCREEN PRODUCTSSolution Proposal

We offer appealing services that emphasize design with various options such as Touchscreen sensors and LCDs (liquid crystal displays) that can be efficiently selected according to the application, as well as customizable cover glass. We also offer the best solution to meet your needs by standardizing applications through the use of a single Touchscreen controller.

VIEW MORE

-

![]()

Touchscreen LCD bonding

-

![]()

Touchscreen with Cover Glass

-

![]()

Cover glass / Acrylic

-

![]()

Touchscreen Film

Value Chains

| Procurement of raw materials | R&D and Design | Manufacture | Logistics | Product use, disposal & recycling | |

|---|---|---|---|---|---|

| Risks | ◦Human Rights Violations by Conflict Minerals ◦Human Rights Violations and Labor Practices at Suppliers ◦Damage and environmental pollution caused by hazardous substance spills ◦Supply disruptions of raw materials and supplies due to conflicts or large-scale disasters ◦Increased procurement costs due to higher raw material prices |

◦Decrease in competitive advantage (novelty, price, etc.) ◦Delayed response to environmentally friendly product needs |

◦Increase in CO2 emissions ◦Environmental Pollution from Wastewater ◦Depletion of water resources ◦Environmental Pollution by Toxic Chemicals ◦Procurement and production stoppages due to natural disasters/accidents ◦Occupational accidents ◦Loss of customer trust due to quality problems (e.g., fraud) ◦Decreased yield due to increased defective products |

◦Human rights violations due to long working hours, etc. ◦Increase in CO2 emissions during transportation ◦Fragmentation of transportation routes due to conflicts or major disasters |

◦ Increase in CO2 emissions ◦ Release of hazardous chemicals ◦ Increase in waste ◦ Claims/recalls due to product defects ◦ Disasters caused by products |

| Opportunity | ◦Growing awareness of supplier stability | ◦Increasing demand for innovative technologies ◦Expanding market for environmentally friendly products |

◦Accumulation of know-how through the upgrading of production equipment ◦Ensuring social trust through thorough occupational safety and health |

◦Response of logistics companies to diverse transportation needs ◦BCP response services of logistics companies ◦Ensuring competitive advantage through stable logistics |

◦Expanding market for environmentally friendly products |

| Corresponding measures | ◦Collecting information on conflict minerals from all suppliers ◦Developing CSR procurement guidelines and understanding their efforts through surveys ◦Considering safe handling when using raw materials containing certain chemicals by obtaining MSDS (safety data sheets) ◦Building a domestic procurement system |

◦Exploring new markets through active overseas expansion ◦Training research and development personnel ◦Reducing the number of used parts |

◦Setting goals for CO2 emissions reduction ◦Environmental education for employees ◦Proper management of wastewater ◦Reducing water consumption by recycling ◦Proper management of chemicals throughout the process from design to disposal ◦Labor environment without human rights violations, including prohibition of forced labor and child labor ◦Sharing and risk assessment education of "Hiyari" and "Hat" at work ◦Safety patrol of production sites by the president or responsible persons ◦Communication with customers ◦Reducing waste by reducing defective rates in the manufacturing process ◦Quality education and improvement activities ◦BCP measures to replace manufacturing lines that were disrupted in the event of a disaster in both Indonesia and Japan |

◦Conducting surveys to suppliers ◦Improving the efficiency of product transportation |

◦Developing environmentally friendly products ◦Safe design of products |

| Related SDGs |

|

|

|

|

|