Top Commitment

The new DMC started after the merger with Seedsware and contributes to solving social issues through business in a wider range of fi elds.

President, DMC Co., Ltd.

Tatsuya Sada

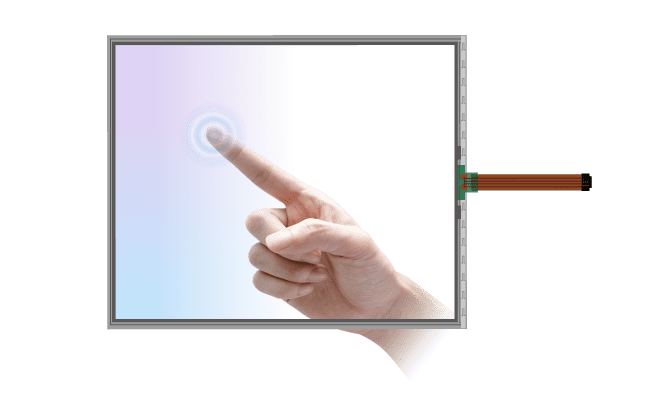

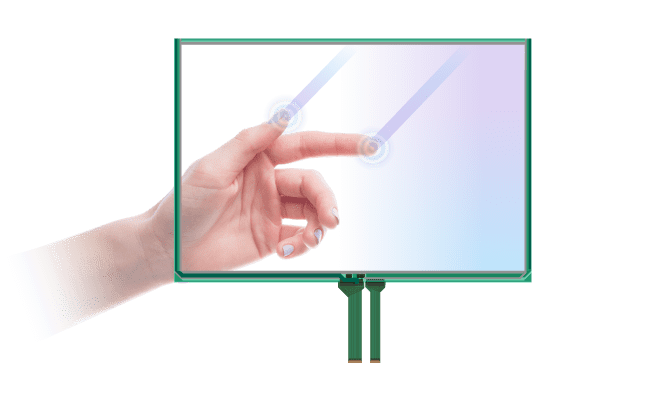

Touch screens that have become an indispensable part of daily life

----- Do you think the market has significantly changed since DMC was founded in 1973 and started manufacturing touch screens in 1991?

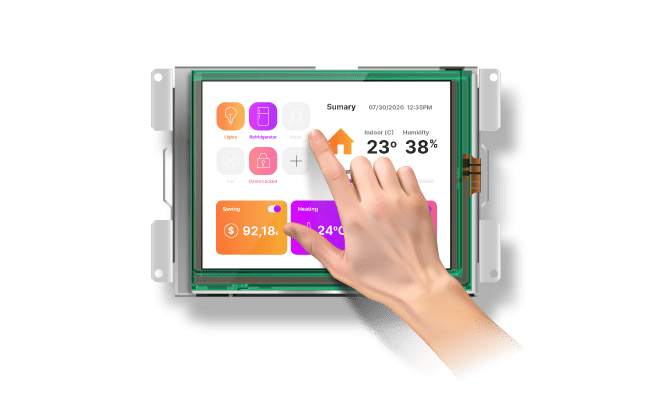

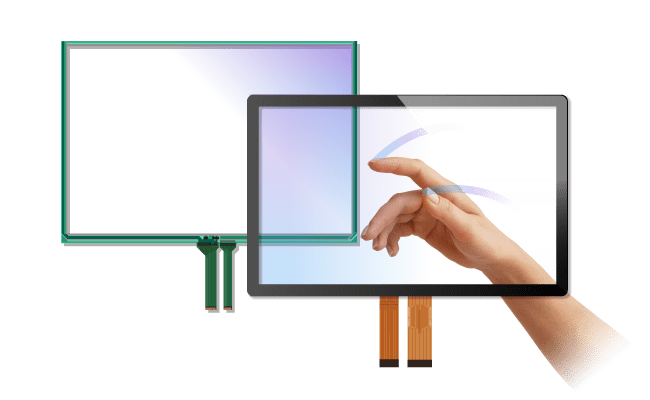

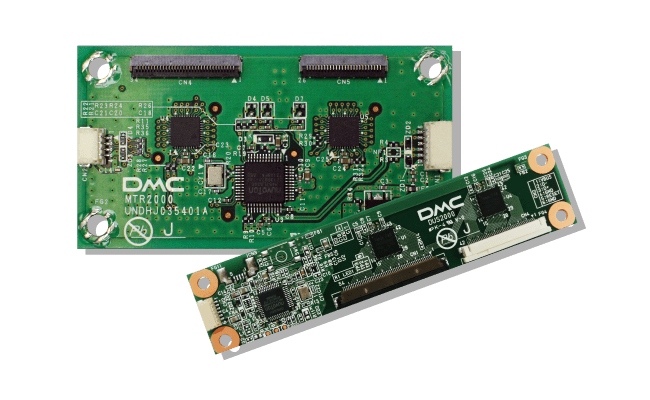

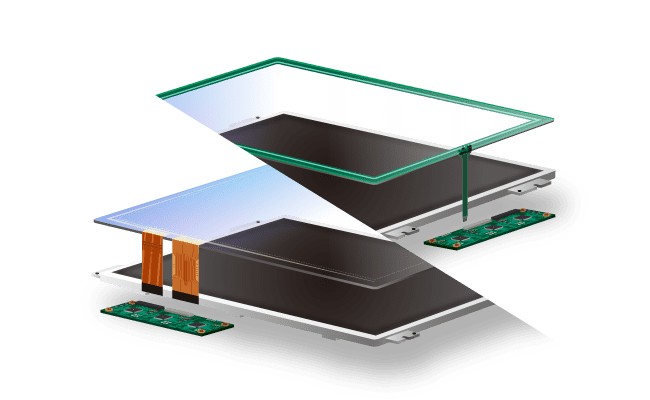

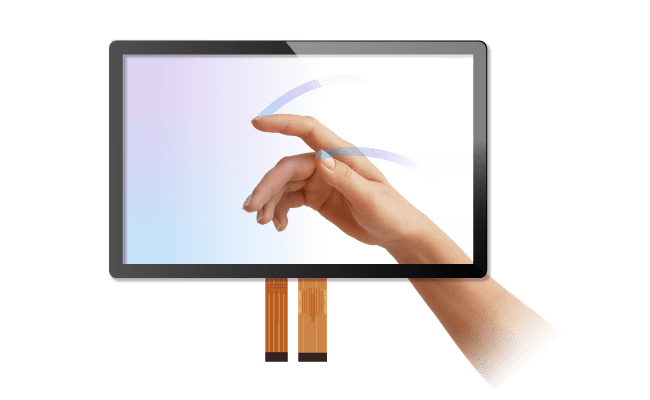

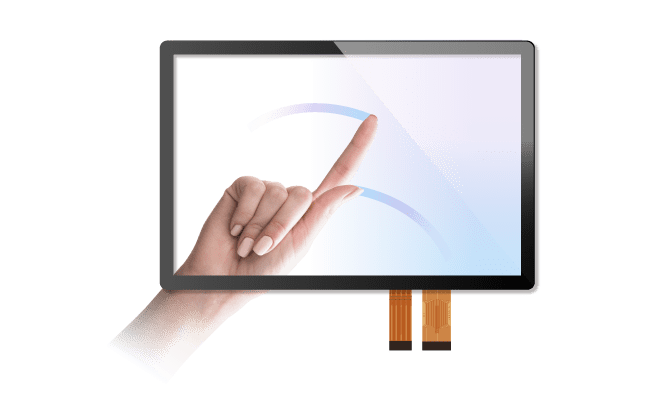

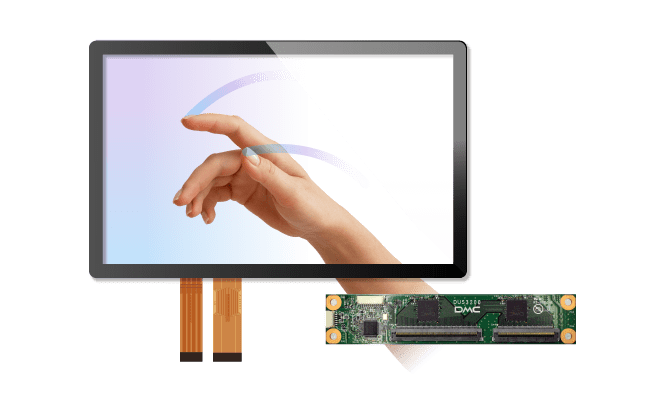

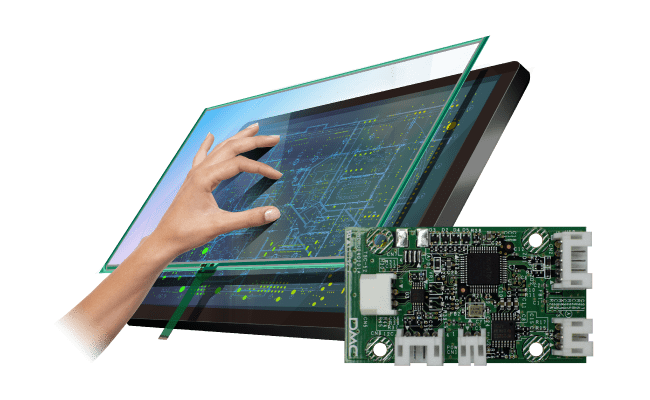

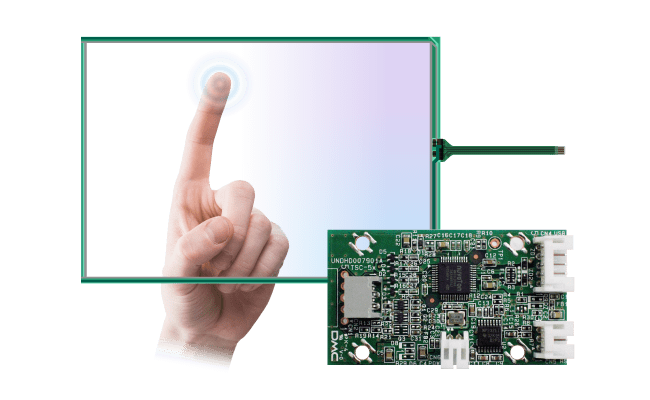

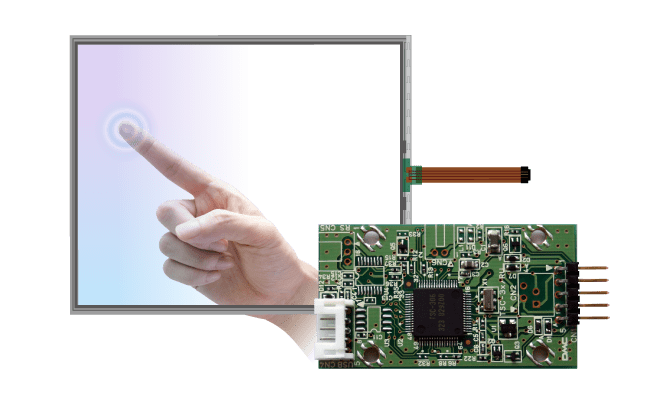

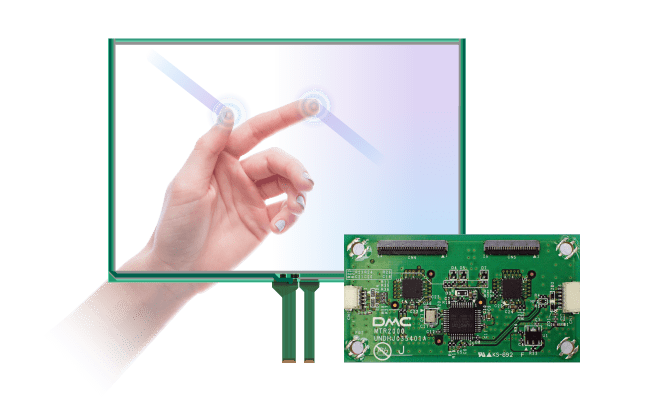

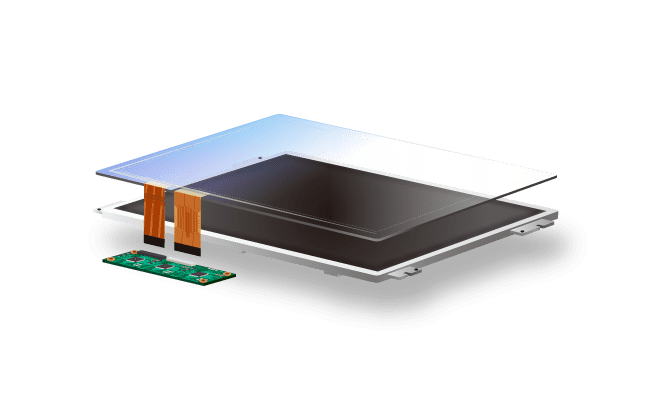

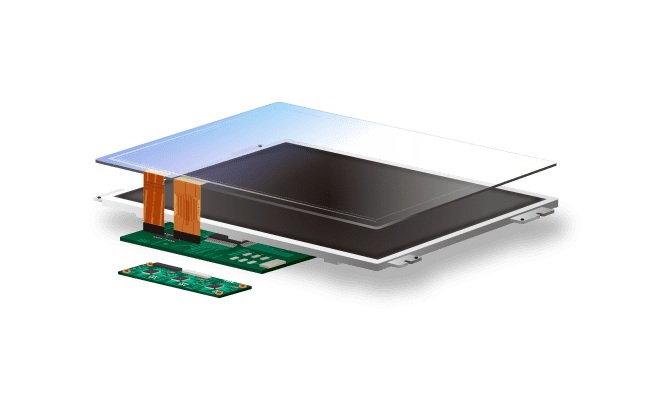

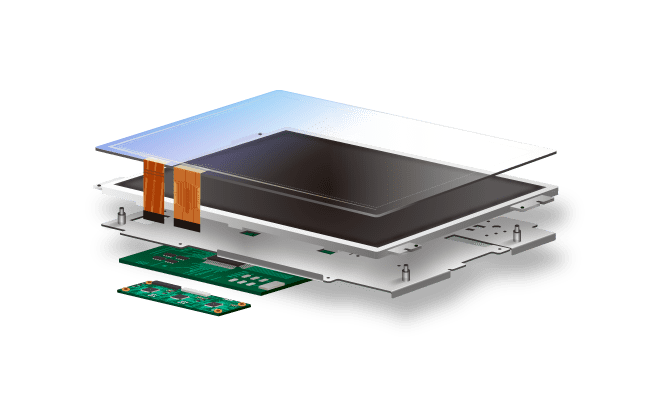

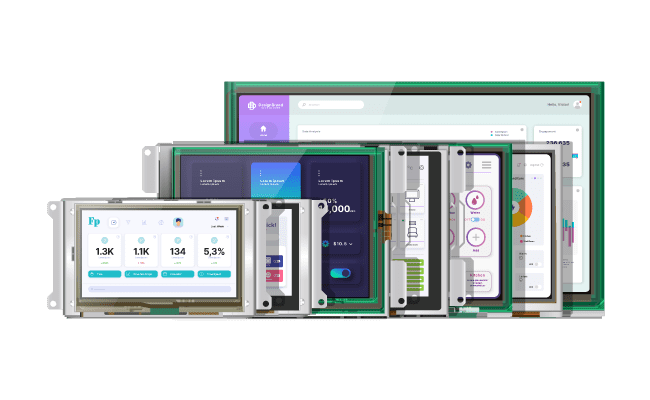

SadaOur core business has been the manufacture and sale of touch screens and related modules based on sensor technology, which is one of our strengths. Recently, however, there has been a high demand for touch screen computers and touch screen monitors that incorporate touch screens manufactured by our company.

WadaI think the change in needs is also due to the shortage of labor due to the decrease in the working population. Most of our products are for industrial equipment used in factories, etc., and the operation of the machines was limited to skilled workers. In recent years, however, the need for simple operability that can be used by less-skilled operators is rapidly increasing. We realize that our products are required to have higher operability as their applications are expanding into areas where the general public operates them, such as POS cash registers and self-service payment terminals in hospitals.

----- On the other hand, there was the COVID-19 pandemic, an event that completely changed our behavior, and I think this may have strengthened interest in some areas.

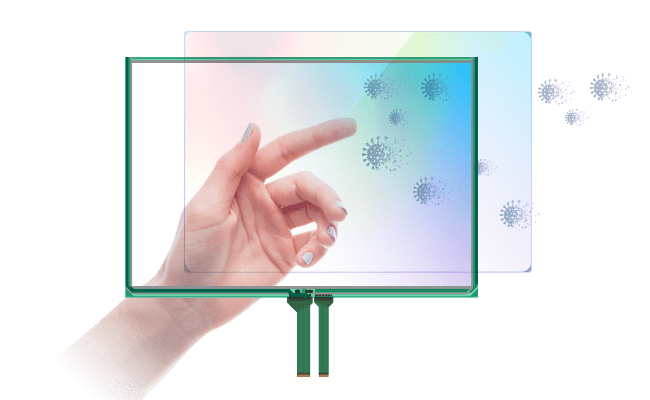

WadaTouchpanels are used in medical equipment for diagnosis, analysis, and testing. As such, there is interest in products with antimicrobial functions that prevent infection even if viruses or bacteria adhere to the panel during operation, and anti-fouling functions that prevent the panel from becoming difficult to see if it gets dirty with fingerprints or blood.

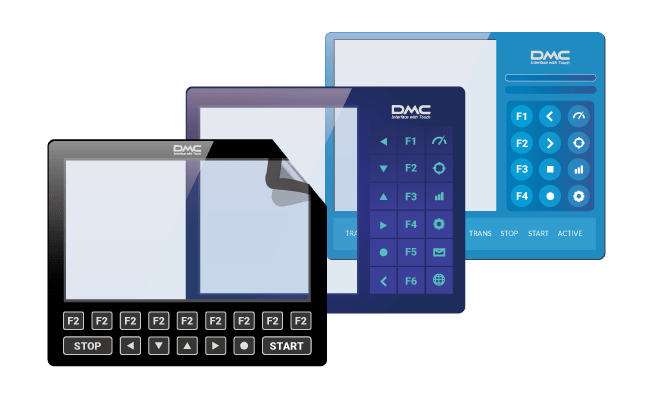

SadaI think demand is increasing in areas closely related to the social issues Japan is facing right now, such as labor shortages and expectations for advanced medical needs associated with an aging society. Under these marketing conditions, we have merged with Seedsware in January 2023, which is also a member of the USCO Group, in order to meet a wider range of needs and contribute to solving our customers' issues. The synergy effect of the technology and know-how possessed by DMC, which has mainly dealt with touch panels and modules, and Seedsware, which has dealt with panel embedded products such as touch panel computers and monitors from a position closer to the product users, has enabled DMC to quickly respond to changes in a wide range of fields and markets.

WadaMany of our customers operate globally, and we expect our market to expand globally as well. However, we believe that the prerequisite for this is to be chosen by our clients as a partner that can work together with them to solve difficult problems. Achieving this is the main goal of this integration. We believe that by working hand in hand with our customers, solving problems one by one, and growing together, we can ultimately contribute to the sustainable development of society.

Management's thoughts and message behind "DUSH", the unified product brand of both DMC and Seesaware

Executive Vice President,

DMC Co., Ltd.

Susumu Wada

Revision of Management Philosophy and the Thoughts Behind It

----- In your management philosophy, which was revised in conjunction with the merger, you state that you “pursue an 'exciting tomorrow' that is happy and sustainable both materially and spiritually.” Please tell us about the thoughts and feelings that went into it.

SadaThe USCO Group, to which we belong, has adopted the slogan “Challenging Today for an Exciting Tomorrow”. In revising our management philosophy, the management team once again discussed what exciting means to us. Thinking back to the past, we agreed that we were most excited when we were passionate about our work, even when times were tough.

For example, when the Great East Japan Earthquake struck in 2011, the area around the former headquarters plant was off limits and production had to be halted. And this was just as we were working on launching a new product in 2010. In order to keep the delivery date to the customer, the employees worked together to overcome the difficult situation by transferring the production of the old products to the Indonesia Factory and finding an outside production partner for the new products. This was a difficult experience for me, but I experienced that when everyone works with passion, an exciting future opens up. We want to be a company where everyone can have this kind of experience and work with passion, and we have incorporated this desire into our new management philosophy.

WadaThe new brand “DUSH” also expresses our thoughts on management. D, U, and S are acronyms for DMC, Unitech (a group company responsible for the development of touch panel application technology) and parent companies USCO and Seedsware. The final H is for Happiness. We do not want to be happy only for ourselves, but to grow and be happy together with all our stakeholders by mobilizing the power of our group. The message is that we will continue to take on challenges without fear of change and make the world a happier place.

SadaIt may be tough to continue to take on challenges, but we will feel more excited to work with our customers to solve their problems, even though we may be facing difficulties.

Toward Carbon Neutrality

----- I hear that requests from customers to reduce CO₂ emissions are increasing as we move toward achieving carbon neutrality by 2050.

SadaWe have set a CO₂ reduction target of 26.6% by 2025, and so far we are making good progress.

WadaA specific example of our efforts is the shift in manufacturing methods. Wet etching (a process that uses corrosion to form circuit patterns on glass or film), one of the manufacturing processes, requires a very large amount of power. We believe that by eliminating this method and converting to a laser-based manufacturing method, we can significantly reduce power consumption. We have already launched a project and are in the process of selecting equipment to implement the method by 2025.

We also see the environmental impact of the transportation of raw materials and products as an issue that cannot be overlooked. We import glass plates used for touch panels from China and manufacture touch panels in Japan and Indonesia, with transportation going back and forth between China, Japan, and Indonesia in the process from procurement to manufacturing. Therefore, by reviewing suppliers and shortening transportation routes, we expect to reduce costs and CO₂ emissions.

SadaThere is also a trade-off between environmental initiatives and profits. Anti-smudge films are used to improve quality, but while using more of them reduces the number of defective panels, it also increases the amount of film waste. From a different perspective, however, the advantages of reducing panel waste outweigh the disadvantages of using film. We believe that it is the responsibility of management to navigate a good balance between this type of profit enhancement and environmental initiatives.

WadaIn recent years, major customers have started to focus on GX (Green Transformation) in conjunction with DX (Digital Transformation), and the industry as a whole is turning in a green direction. We believe that these types of trends will accelerate in the future, and we are committed to developing power-saving equipment.

SadaAll of these initiatives are halfway through the process, but they are important efforts that will lead to reductions in man-hours and raw materials, as well as to reductions in disposal and waste, which we have been promoting for a long time. In the process it will promote product improvement and quality enhancement, which should lead to better corporate management. We will contribute to the realization of carbon neutrality through our creative initiatives while raising awareness of sustainability throughout the supply chain, from upstream to downstream.

To Be a Company That Is Permanently Needed by the World

----- What is the intent of your vision of “a leading interface solutions company, a 101-year-old company that continues to grow and adapt to change”?

SadaOriginally, we stated that we would become a 100-year-old company (a company that perseveres over 100 years). However, one of the employees at the Indonesia Factory told us, “We want to be a company that not only aims to last 100 years, but also exist in perpetuity even after that. So why don't we make it 101 years?”

WadaWe are also a global company with a diverse workforce, with a production facility in Indonesia and branches in Taiwan, Italy, and the United States. International employees are ambitious and passionate. I hope Japanese employees will learn from this. The chemical reaction that occurs when diverse personnel stimulate each other and cultivate their know-how, in which different strengths are combined, should make it possible to propose more effective solutions. We are convinced that the accumulation of experience gained in this way and passed on to the next generation will be the driving force behind the realization of a 101-year-old company.

----- Could you give a final message to your stakeholders?

WadaIt is often said that a company is its people. As a member of management, I intend to listen carefully to each employee's voice from his or her perspective and evolve the company into a place where the strengths of each and every employee can be brought out even more fully.

SadaI told the new employees who joined us in FY2023 that I want them to always be willing to think independently, confront challenges, and devise approaches that will lead to solutions. This is a very important factor in solving the problems of our customers and, by extension, of society. We aim to be a company that is loved and needed by the world 101 years from now and beyond, by continuing to think and work with passion and pride to create an exciting tomorrow and to pass our thoughts on to the next generation who will lead the future.