Product Safety & Security

Quality & Environmental Policies (Device Business)

Based on our management philosophy of growing together with our customers by taking on challenges with passion and pride, and pursuing an “exciting tomorrow” with happiness and sustainability both physically and spiritually, we have set out the following quality and environmental policies.

- We will provide high-quality products around the world that satisfy customer requirements, laws, and regulatory requirements.

- We will measure and analyze the response of the customers and regions we serve to continuously improve our products, processes and systems.

- We seek to reduce our environmental footprint through our commitment to preventing pollution, reducing waste and saving resources.

President. Tatsuya Sada

Quality & Environmental Management System

DMC's quality assurance system aims to meet customer expectations for safe, high-quality products and services. We conduct yearly management reviews to examine and evaluate the state of our quality management system in line with our quality and environment policies and quality targets to ensure constant improvement. Yearly audits are conducted by certified internal auditors. DMC shares progress in target achievement and product quality issues at Quality and Environment Council meetings held once per month, and promotes the PDCA cycle to ensure that all employees understand quality and environment policies and achieve ISO targets established by each division. In addition, the Shirakawa Factory, Indonesia Factory, Tokyo Office, Osaka Office, and Nagoya Service Office acquired ISO certification for the design, development and production of touchscreens. The Iwaki Factory, which began operations in October 2021, also obtained ISO 9001 certification in August 2023. (ISO certification coverage of production sites: 100%)

Quality & Environmental Management System Diagram

Approaches to Product Quality Improvement

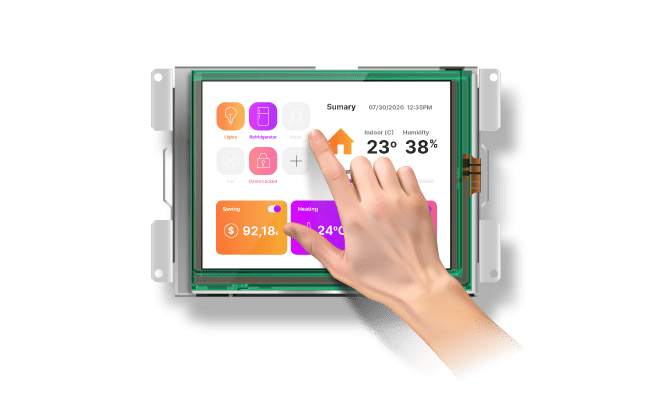

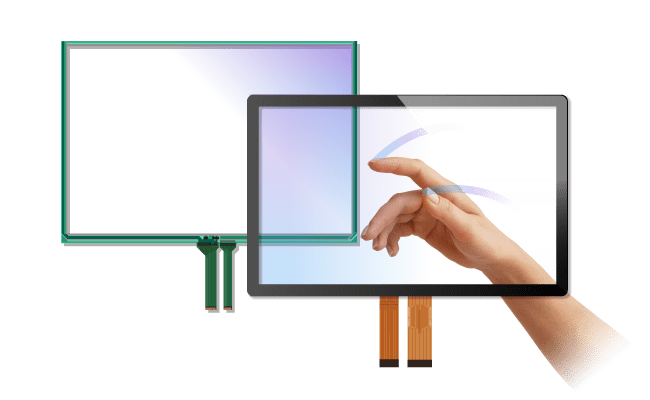

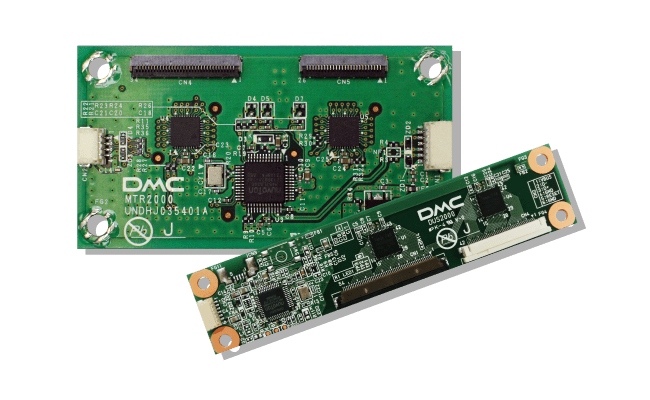

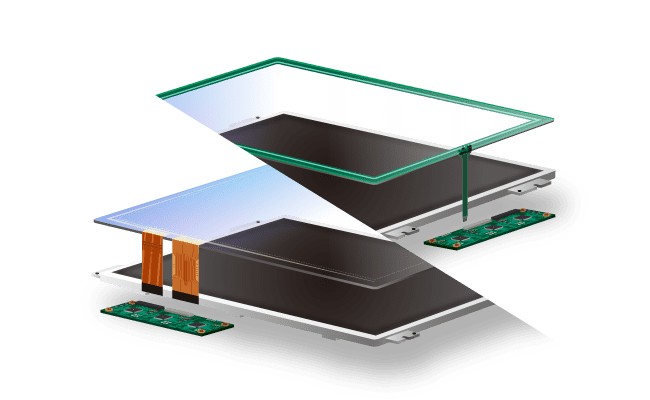

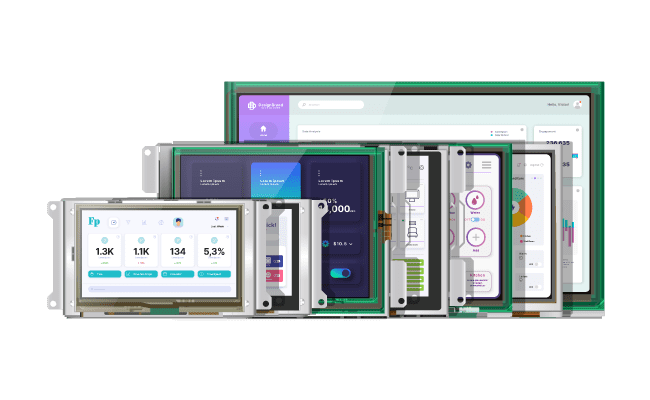

We are taking various initiatives to provide higher quality products. The strength of our Group is that we have the technology, know-how, and systems that can precisely respond to the sophisticated and diverse quality requirements of our customers. As such, we have built a system that allows us to make the most of these strengths.

Monthly New Product Strategy Meeting

Product strategy meetings are held regularly (once/month) with the President and representatives from the Planning and Development, Sales, and Manufacturing departments, in a system that allows us to analyze customer needs and reflect them in our products.

Quality Improvement Activities

With the aim of improving production technology and productivity, we conduct initiatives that originate from operations that occur daily at the manufacturing site, and quality activities that originate from defects such as complaints. Regarding these, related departments implement initiatives by topic and report to the next meeting with important topics communicated down as instructions from the higher-level meeting.

Communication between engineering staff and customers

It is important for us to accurately understand customer requests and consider detailed specifications for products. Therefore, personnel in charge of engineering visit customers with the personnel in charge of sales to have direct communication with customers.

Quality Assurance Patrols

The number of complaints in FY2022 increased by 54% compared to the previous year (net sales subject to complaints increased 30% from the previous year). This was a 76% increase compared to the FY2022 goal of reducing the amount of losses due to complaints by 13% compared to the previous year. The increase was mainly due to the occurrence of careless mistakes in large-scale projects and an increase in re-inspection costs. Since the ratio was particularly high at our Indonesia Factory, we dispatched skilled personnel from Japan to help reduce the number of complaint. In FY2022, there were no serious product accidents, such as major injury or equipment damage, involving customers or within the company.

Improvement of Customer Satisfaction

DMC Sales Division conducts a customer satisfaction survey with 20 items in seven categories (sales, sales promotion, delivery, quality, technical capability, competitiveness, and other) once a year targeting its major sales agents, and shares the results as customer voices among the relevant departments and divisions. This allows us to identify issues and improve products with the goal of maintaining customer trust. In FY2022, DMC distributed questionnaires to 10 sales agents (8 in Japan, and 2 overseas), and the response rate was 100%.

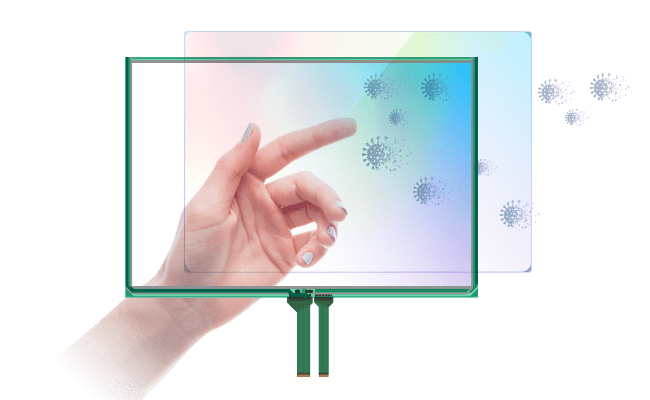

Ensuring Product Safety

Proper Chemical Substances Management

DMC performs proper chemical substances management from design to disposal to ensure the safety of our products.

We use chemical substances for our products in accordance with the laws and regulations specified by each country and promote the reduction of hazardous chemical substances that may affect people and the environment. We assess the safety of all our products to ensure that hazardous chemical substances restricted by the RoHS Directive, including lead, mercury, cadmium, and hexavalent chromium are not contained in or attached to our products, or to ensure that the amount of those substances contained in or attached to our products is less than what is stipulated by laws and regulations. For substances judged to pose a safety risk, we reduce or cease use to ensure product safety.

We obtain a Material Safety Data Sheet (MSDS) that describes the danger and toxicity, and precautions of chemical substances and raw ingredients containing specific chemical substances to ensure safe handling until disposal.

The Quality Assurance Division plays a central role in the proper management of chemical substances and acquires the most up-to-date information and understands trends to ensure a prompt response to revisions in a wide range of laws and regulations regarding chemical substances.

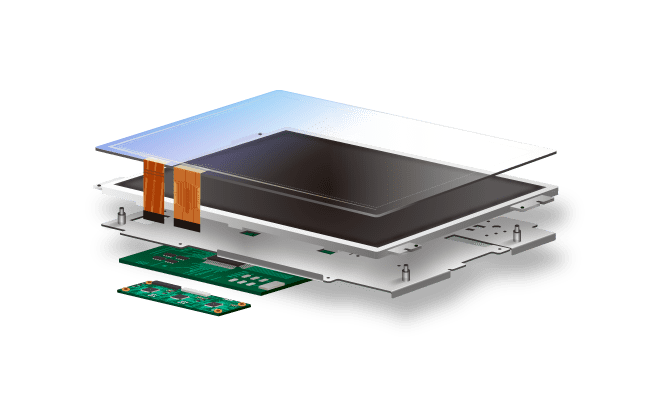

Because touchscreens and unit products used in electronic devices and equipment in a wide range of industries have a large number of parts, we outsource investigations of hazardous substances to specialist external companies.

Product Safety Design

In each process of development, design, and manufacturing, we take measures to ensure the safety of our products during their use. In recent years, new scribing machines have been introduced to prevent damage and injury from the edges of glass sheets.

Training on Quality

In order to continue to create products with quality and safety that satisfy our customers, training and workshops take place in each department throughout the year. In FY2022, the following in-house training sessions took place online.

Main Quality Training

| Training Topics | Times Held | Participants |

|---|---|---|

| Quality ISO manual course | 10 times/year | All employees |