Environmental Conservation

Environmental Management System

The DMC Group strongly believes that business activities and environmental conservation should be part of the same decision-making process. We implement our environmental management system into each business activity process to promote its environmental management.

Chaired by the President, the DMC Group ISO Promotion Committee was established as the highest organ of decision making for environmental management. The ISO Promotion Secretariat handles the management of factories, divisions, and business bases under the supervision of the ISO Promotion Committee. Each division establishes Quality and Environmental Plans and reports progress and results at monthly Quality and Environmental Conferences that the President attends to ensure the effective application of the PDCA cycle.

Internal Audit

The Group conducts annual audits by certified internal auditors to confirm conformance with ISO 14001 and the effective functioning of the environmental management system.

DMC holds meetings before and after audits to clarify priority items, confirm the content identified by auditors with the related divisions and departments while the ISO Promotion Secretariat shares issues to promote improvement throughout the DMC Group, and handles progress management of the issues until the next meeting aiming to improve the quality of internal audits and environmental activities performed by the DMC Group.

In-house Education

The DMC Group considers human resource development critical to the promotion of its environmental management activities. To this end we have established a curriculum, as shown below, to provide individual employee education based on specialization and level.

- ISO awareness training: All division managers provide opportunities for employees to recognize and learn quality and ISO policies in order to maximize business results by linking division goals and individual targets. Employees themselves record these details in the prescribed format where they are then managed by the ISO Promotion Secretariat.

- Internal and external training related to CO₂ reduction: After training, reductions are examined and operational tests conducted, such as electricity consumption in the factory, as individual themes.

Material Balance

-

Resources : 7,305thousand Wh

-

Fuel - Petroleum : 0thousand l

-

Water withdrawal : 38thousand m³

- [ Major Materials] ] Highly functional resin, plate glasses, etc.

-

Gasoline : 31kl

-

CO₂ : 4,796t-CO₂

-

Wastes : 310t

-

Water discharge : 36thousand m³

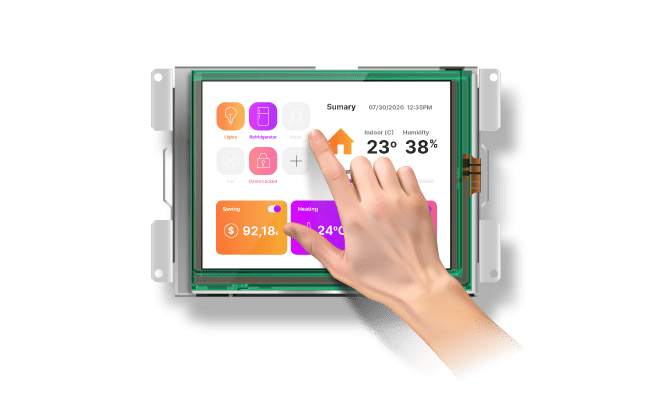

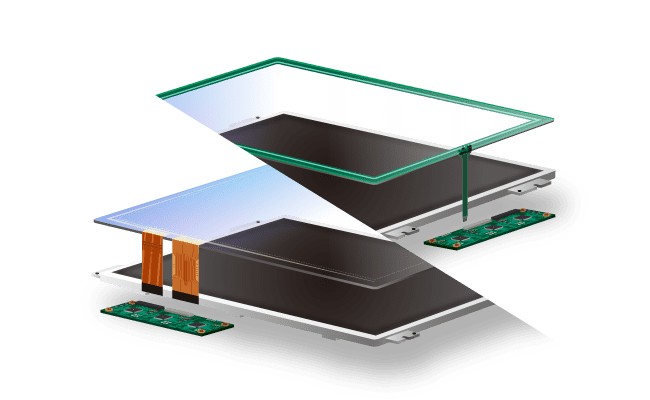

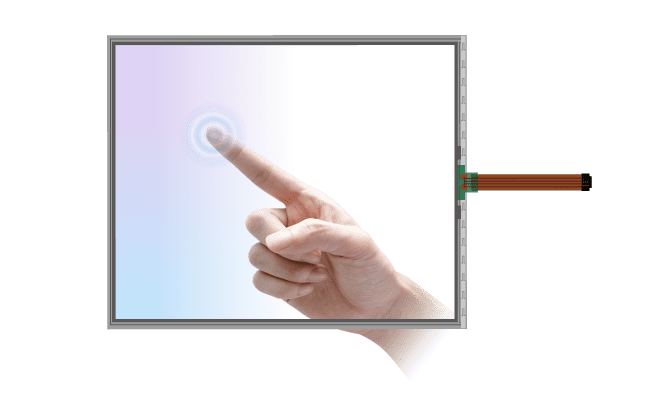

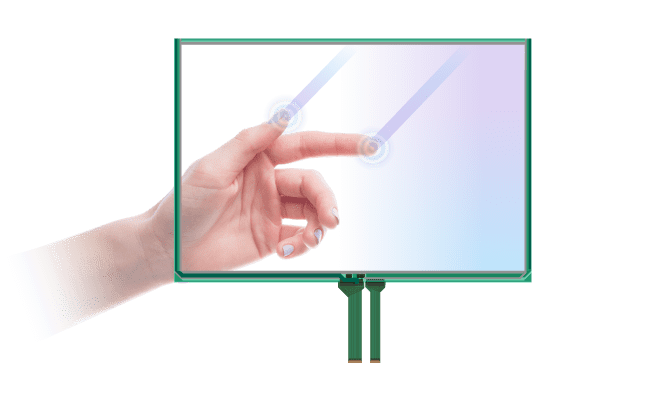

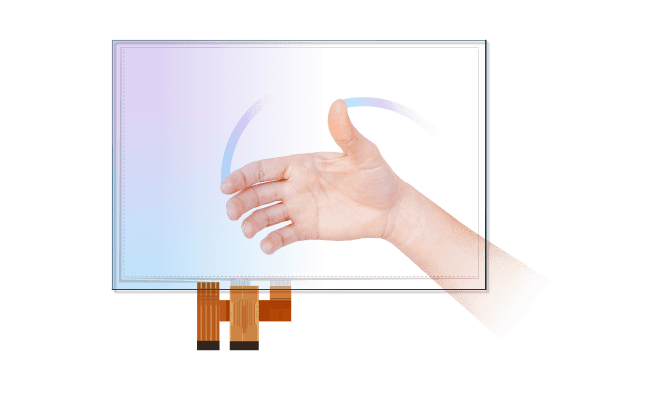

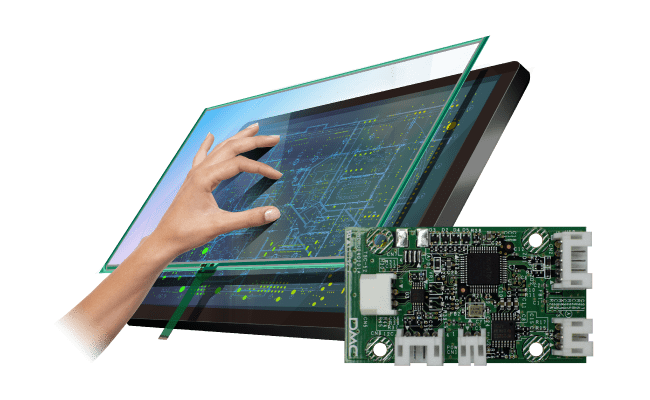

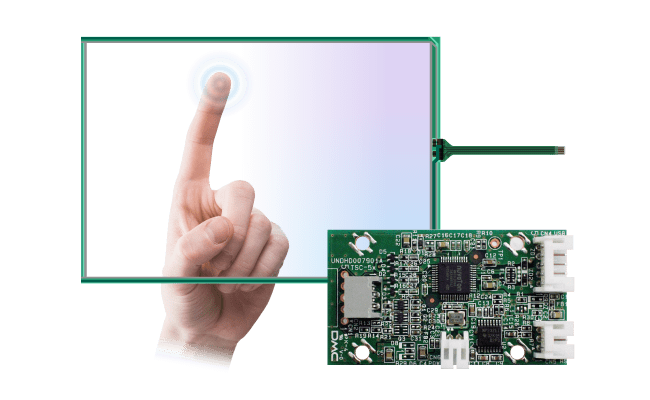

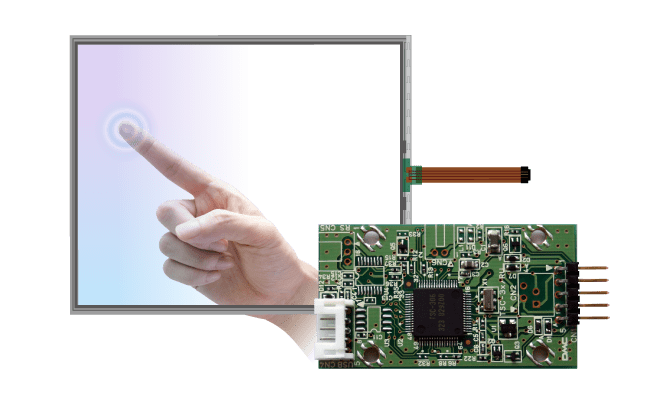

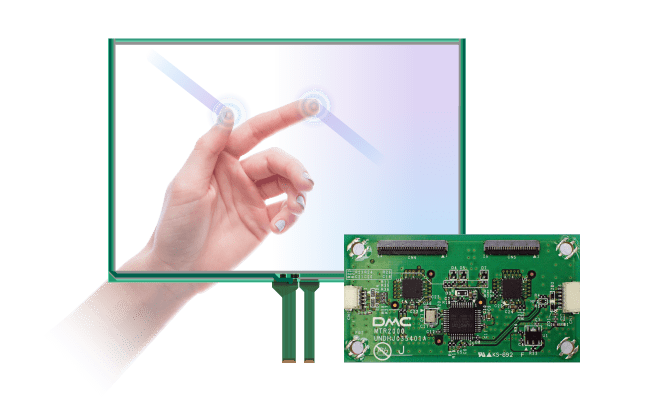

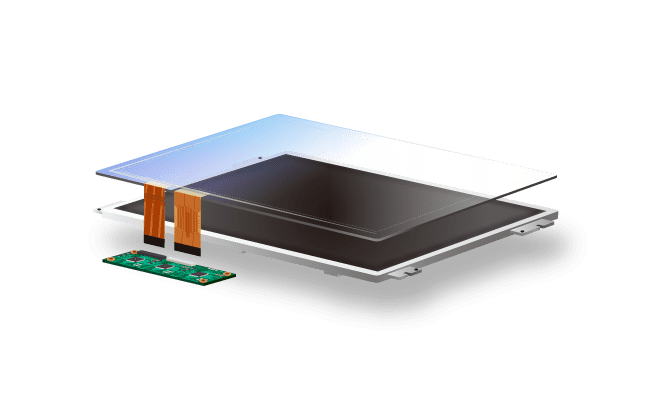

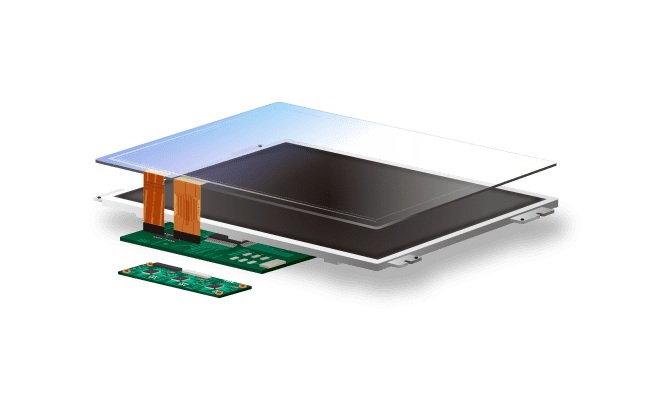

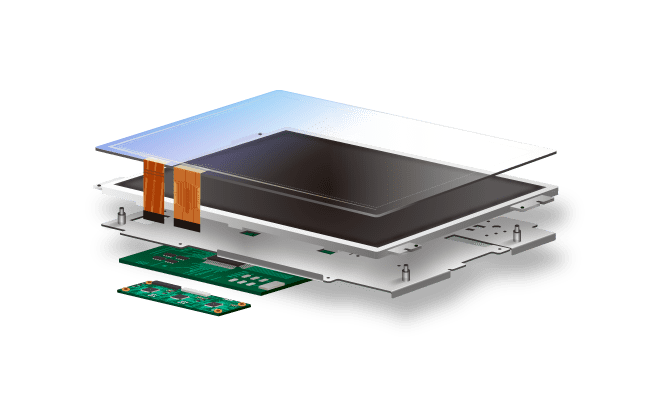

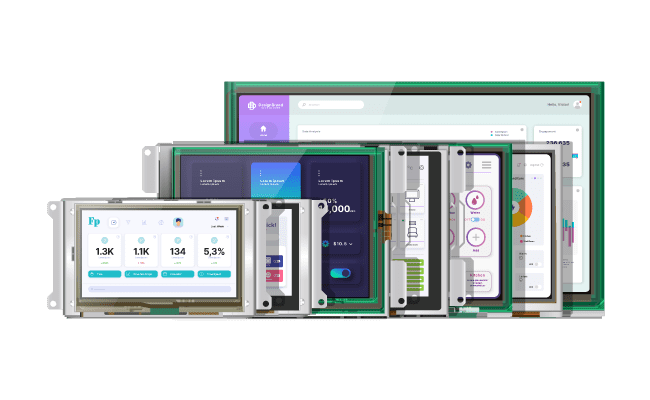

- [Products] Touchscreens, LCD modules

-

CO₂ : 71t-CO₂

Response to Climate Change

In the face of climate change, DMC considers the reduction of CO₂ emissions that contribute to increasing temperatures as our corporate responsibility and works toward this in all phases of the production and delivery of touchscreens through the eff ective use of energy and other approaches.

Progress Towards CO2 Emissions Targets

The Group aims to reduce Scope 1 and 2 emissions at our company, Indonesia Factory, Shirakawa Factory, and Iwaki Factory by 26.6% by FY2025 as an interim target toward achieving carbon neutrality by 2050 (with FY2018 as the base year). Scope 1 and 2 emissions in FY2022 increased by 25.7% compared to the previous year. This was 17.4% lower than the 55% reduction in the baseline year for Scope 1, which was set as a single-year target for FY2022, and 7.6% higher than the 10% reduction in the baseline year for Scope 2, meaning that we did not achieve our targets. The main reasons for the increase were a greater number of operating hours at the domestic and Indonesian factories due to increased production, and year-round operation at the Iwaki Factory. We will continue to strengthen energy conservation measures to promote CO₂ reductions.

Scope 3 Emissions

-

The DMC Group calculates greenhouse gas emissions in all its corporate activities, from upstream to downstream, based on the GHG Protocol, an international standard for companies to calculate and report greenhouse gas emissions throughout their supply chains. In FY2022, Category 1 emissions, which account for the highest proportion of CO₂ emissions, increased by 23.6% compared to the previous year. This was due to an increase in the amount of glass purchased due to increased production, as well as bulk purchases of eligible items in response to the semiconductor shortage and EOL. Clarifying emissions throughout our supply chain and identifying the potential for reducing emissions will lead to CO₂ reduction and contribute to the fight against global warming.

-

FY2022 CO₂ Emissions by Scope & Category (t-CO₂)

Scope & Category Emissions SCOPE 1 71 SCOPE 2 4,796 SCOPE 1 + 2 4,867 SCOPE 3 18,970 Category 1 Purchased Goods and Services 14,970 Category 2 Capital Goods 128 Category 3 Fuel- and Energy-related Activities (not included in scope 1 or 2) 515 Category 4 Transportation and Delivery (Upstream) 1,952 Category 5 Waste Generated in Operations 10 Category 6 Business Travel 113 Category 7 Employee Commuting 260 Category 11 Use of Sold Products 1,022 Total 23,837 * Scope is production sites (100% coverage). Seedsware Corporation's production site in Osaka is excluded from the scope as it was merged in 2023.

Management System & Operation

General Affairs Division takes charge of company-wide improvement activities. We conducted energy-saving campaigns, shifted to LED lighting, implemented highly efficient PC monitors and other devices, and shifted business vehicles to eco-friendly vehicles throughout the company. We are also continuously working to improve the efficiency of energy use in our production processes. At the Shirakawa Factory, we installed equipment that can adjust humidity and temperature by block in manufacturing areas and automatic turn-off lights using motion sensors in common areas, and continue with the Cool Biz campaign to limit the use of air conditioners. As a measure to further reduce electricity usage going forward, in FY2022 we checked and tested electricity usage and the effectiveness of measures at our Iwaki Factory. Specifically, it was demonstrated that electricity usage could be reduced by 25% compared to the previous year by better using air conditioning, which uses a high proportion of electricity. As such, we will make efforts to rollout the results of this verification to other factories.

-

Power Usage*

-

CO2 Emissions (SCOPE 1+2)*

Approaches to Waste Reduction

The DMC Group will make eff ective use of resources to create a sustainable, recycling-oriented society, and will set and work toward waste reduction and recycling targets.

Management System & Operation

-

DMC issues an industrial waste management manifest to monitor waste discharged from its factories and offices. We utilize an exclusive database to ensure uniform control over the management of disposal service providers and the industrial waste management manifest to continuously monitor the status of waste disposal. Because reducing the defect rate in production directly leads to waste reduction, efforts that DMC make for the improvement of production processes include the establishment of structures to maintain the best quality.

-

Volume of Waste Disposal

Approaches to Paper Reduction at DMC

The DMC Group digitalizes and shares documents, and manages decision-making processes, order sheets, and work hours by computer to reduce paper. We continue working on reducing paper while improving our business processes.

Water Resource Conservation

Infrastructure improvement has been delayed due to an increase in population and demand for water resources that have accompanied economic growth. This has accelerated water shortages and pollution, which has had a signifi cant impact on our lives and environment. The DMC Group considers the eff ective use of water in manufacturing and the conservation of water resources.

Management System & Operation

-

The DMC Group established an integrated management system for water and environmental quality to promote water resource conservation. We also apply the PDCA management cycle to improve environmental management. We select wastewater treatment plants and outsource the neutralization of wastewater discharged at our plants to reduce environmental load. The Indonesia Factory has introduced and is operating a recycling system for water-intensive processes in order to make effective use of precious water resources, and is working to continuously reduce its water usage.

In addition, our domestic and Indonesian factories carry out appropriate wastewater treatment in accordance with laws and regulations, conduct regular biochemical oxygen demand (BOD) inspections, and submit test result certificates to public institutions to confirm that there are no problems.

-

Water Intake

Reducing the Discharge of Chemical Substances

Management System & Operation

DMC works to reduce the use of chemical substances that may directly influence the environment through its production processes. No discharge or transfer of PRTR substances were detected in the fiscal year.

Third-Party Assurance